Advance Certificate EV Technology & Business management

India represents the fourth largest automobile market in the world and the second-largest two-wheeler market. It is also a country with massive dependency on oil imports, with a USD 112 billion oil import bill in FY19. EV market likely to be Rs 50,000-cr opportunity in India by 2025. India is expected to command leadership in EV space with a projected share of 30% of new vehicles sold by 2030. Government has tabled a proposal to have a charging station every 3KM in major cities & every 50KM on major national highway. Growing Sales of Electric Vehicles - A Significant Opportunity for Li-ion Batteries Market. The government plans to offer $4.6 billion in incentives to companies setting up advanced battery manufacturing facilities as it seeks to promote the use of electric vehicles and cut down its dependence on oil, according to a government proposal seen by Reuters.

In this fast moving Electric Vehicle Market Academy of EV Technology a fully focused in Entrepreneurship development offering a startup and business friendly course to make you or your organization to flourish in this new age technological market.

This course will deliver from basic of EV to EVSE equipment like Lithium-ion battery, Battery pack assembly process, EV Motor, Charger, charging station development and all others parts/ equipment’s calculation, selection, building a Legal Foundation, Understanding Finance Basics, Business Planning and Fundraising.

TRAINING METHODOLOGY:

Live Interactive Classes::

AEVT Live Interactive Class, where students and teachers meet together at schedule class time with whiteboard, voice and live video, Lectures and Question answer occur at the same hour.

Our expert faculty members take session on each paper that is delivered through live sessions. These sessions are joined by students from India and Abroad. Trainers will discuss in each class session about Key concepts, whiteboard calculation, design, costing, documentation, case studies and real life examples. Students also get chance to clarify their doubts / academic clarifications. If by any chance you miss these live classes, don't worry, each class recorded sessions are uploaded in the AEVT E-Library/LMS.

Hands-on Practical

We know that only theoretical knowledge by online or virtual classes are not sufficient to get full expertise. An individual needs a practical exposure to flourish in a Job or business market.

So we offer practical session at AEVT Lab/Workshop after completion of live interactive online classroom session .In this approach a trainees can fulfill his/her knowledge in a very effective way and time.

We offer project-based blended learning experiences that promote academic and career success for Technical Education.

Teaching and Learning Material

AEVT have dedicated online library (AEVT E-Library) facility for students and stored all Learning Material (E-book, class recording, business releated documents) at AEVT E-Library.

AEVT E Library System provides access to more than 100 + e-books covering all fields of knowledge, e.g. EV Battery - BMS, Charging Station Design, Installation, Government rules and Business opportunity etc and also we have a huge collection of national and international journals, case studies, research papers.Student can access this E-library for self study.

Eligibility

For Entrepreneurs, Startups:

Minimum Educational Qualifications: 12th Pass

Minimum age 18 years, No Upper Age bar

Medium:

English

Dedicated Service Desk for Startups - EDP Desk

"Ringfenced resource to support your business".

GATE Trust dedicated service desk will provide you with access to a group of engineers, advisors to supporting you and your business needs.

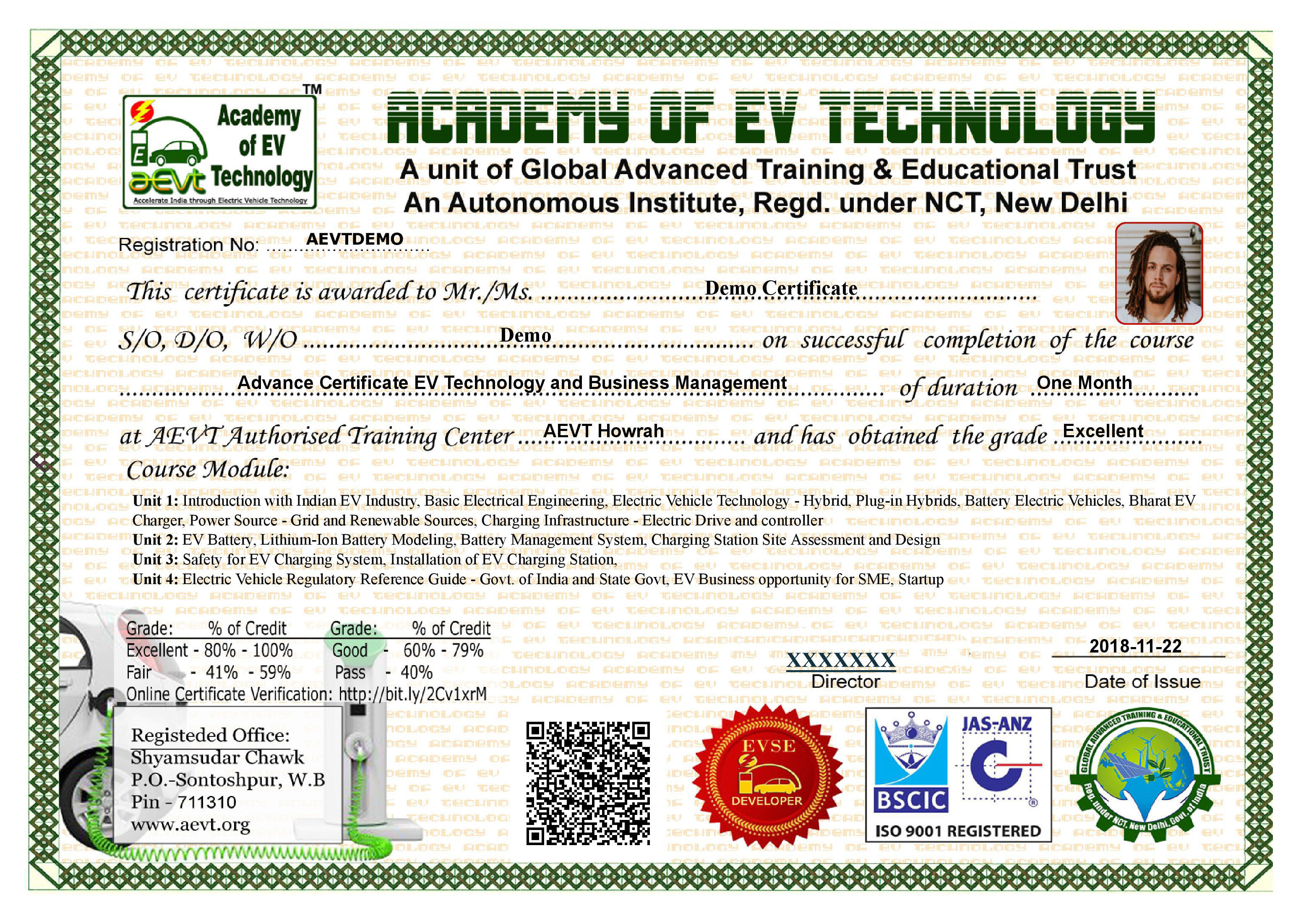

Certificate will be Awarded by

Academy of EV Technology, A Unit of Global Advanced Training & Educational Trust, Regd. under NCT New Delhi, Govt. of India

Online Virtual Class and Offline Practical Course

Course Syllabus:

Unit: BEE

- Major Components in an Electric Vehicle Powertrain - Vehicle Dynamics, Controllers

- Different Types of High-efficiency Motor Technology

- Motor Types

- Selection and sizing of Motor

- Motor Control Functions and Applications

- Selection methodology

- Power Converters

- PID Controlled PWM

- Others Electronic components - Switches, High-performance Control Circuit, Microcontrollers, Gate Drivers, Snubber Circuits, Electric engine, Regenerative braking

- Grid and Renewable Sources - Effect of EV charging on the Distribution Grid

Unit: EVT

- Electric vehicle configuration Vehicle Dynamics

- Types of Electric Vehicle -

- Hybrid Electric Vehicles

- Plug-in Hybrids

- Battery Electric Vehicles

- Type of Charger

- Clarification & Specification Discussion

- Bharat EV AC Charger (BEVC-AC001)

- Bharat EV DC Charger (BEVC-DC001)

- DC Fast Charging

- Basic principles of regenerative braking, Basic principles of conventional braking

BFC

A brief classification of li Ion cell technology and its electro-chemistry. Advantage and disadvantages of over different cell technologies.

- BATTERY ENERGY STORAGE SYSTEM (BESS)

- Relationship between Power and Energy

- Energy storage capacity

- Type of Battery / Cell

- Lithium-ion cells Cathode and Anode Materials

- Type of Lithium-ion Cell

- Main characteristics of lithium cell chemistry types

- Comparison of Lithium-ion Chemistries

- Safer battery materials

- Indian Li-ion Battery manufacturers

BCP

Know your Lithium-ion Cells, Cell Specifications & Performance Parameters. Classification of li-Ion cell technology and its electro-chemistry. Advantages and disadvantages of over different cell technologies

- Capacity, Capacity Retention

- Rated Voltage and Operating Voltage

- cell Datasheet

- Working voltage, Self –discharge voltage

- Continuous current and Peak Current

- Constant voltage / constant current(CVCC)

- C-rate, c-rate effects

- State of Charge (SOC)

- Li-ion Battery Voltage vs SoC

- State of Health (SOH)

- State of power (SOP)

- Internal resistance

- Depth of Discharge (DoD)

- Cycle life of Li-ion batteries

- Lithium Batteries Degradation

- Lithium Ion Battery Failure Modes

- Battery Thermal Runway

- Degrade of Battery Pack cycle

LiCC

An industry detail of Li-ion battery cells, covering the most popular sizes, formats, and chemistries. Given the diversity of Li-ion cells available, the focus is on cylindrical and prismatic cells in metal cases. A brief discussion on li-ion cell chemistry, Cell Anode, Cathode, Electrolytes, binder and Separators materials

- Cell Chemistry Trends

- Cell Anode and Cathode materials

- Cathode Metal Composition

- Active Material, Inactive Material, SEI formation

- Dendrite growth

LiCA

A brief discussion on insights into architecture, design and manufacture of electrodes for lithium-ion cell, Cell Anode, Cathode, Electrolytes, binder and Separators materials.

- This chapter investigates the effects of electrode thickness, porosity, pore size and particle size at the electrode level.

- Architecture design and manufacturing processes for high-performing lithium-ion batteries

- Lithium ion battery Basic Structure

- Cell components

- Anode, Cathode, Electrolytes and Separators materials

- CID, PTC, Safety Vent, Gasket, Plastic Parts

- RAW MATERIALS TO SUBCOMPONENTS

- Common sizes of cylindrical Li-ions

BTM

This chapter identified analyses and approaches that engineers should consider when they design a battery thermal management system. A brief discussion on Thermal Design of Battery Pack.

- Thermal runaway of Battery Pack

- Anode active material failure mechanism

- Cathode active material failure mechanism

- Electrolyte failure mechanism

- Separatore failure mechanism

- Current collector failure mechanism

- Required Functions of Thermal Design

- Low temperature effects

- High temperature effects

- Modes and Function of Battery Thermal Management Systems

- Air Cooling System

- Liquid Cooling System

- PCM material cooling system

BMS

Learn the high-level basics of what role battery management systems (BMSs) play in power design and what components are necessary for their basic functions.

- What the BMS does for battery?

- Function of BMS - Safety, Performance, Longevity, Consistence, Temperature Monitoring and control

- Type of BMS

- Cell Balancing

- Real Time Operating System of BMS

- Example of BMS Wiring Diagram

- How we can select perfect BMS for your battery pack?

BPC

Battery pack differ in size, geometry, and individual cell parameters as capacity and supplied power. A brief discussion on li-ion cell selection, BMS selection for different types of battery.

- Design Considerations of Battery Pack

- Cell Selection

- BMS Selection, Thermal Selection

- High Voltage Side Design

- Low Voltage Side Design

BPS

A battery pack consists of cells connected and made into modules, and modules connected into series and parallel connections to suffice the overall load requirements. A brief discussion of different sizes of battery pack used for electric vehicle & energy storage.

- How to make a Battery Pack?

- The basic calculations that are used in battery design

- Battery pack Technical Specification

- Battery pack designing

- Battery Module and Battery Pack Construction Methods

- Cylindrical and Prismatic Battery Pack

BPA

A brief discussion of battery module/pack making equipment/accessories. Trainees can learn how to make battery modules and Pack.

Battery Pack Accessories

- Material need to assemble battery Modules & pack

- Wires, connector selection, heat shrink, cell holder

- Different types of accessories related to battery pack construction

Battery Module & Pack Making

Battery module / Cell block assembly process- Supply and testing of battery cells & sorting

- Cleaning of cells (plasma cleaning)

- Stacking of modules to form cell block

- Module Formation, Spot Welding, Laser welding

- Thermal management - Application of glue,

- Insertion of cells in modules- Pre-assembly

- Busbar installation

- Module BMS integration, Testing

- Screw fitting of battery module housing

- Integration of cell block in pack

- Application of temperature conductive paste

- Screw fitting of battery housing (housing substructure + housing upper structure)

- Flashing of modules

- Leak testing (helium)

- EOL testing (source-drain)

- Insulation test

- Failure test

CPT

Battery cell testing helps develop better electric vehicle batteries that pack more power density to give longer range performance. Batteries go through an acceptance inspection before they are put together into modules and packs.

- Cell, Module and Pack industry slandered Test

- Testing Equipments and Lab

BPAL

A brief knowledge of Battery Pack Assembly Line development, required machinery details (manual, semi-auto and automatic production line), national & international vendors contact details, required lenience and documents, Financial Report.

Battery Pack Assembly Line

- Manufacturing process of battery pack

- Safety Considerations for BMS (Thermal Runaway, Short Circuit Detection etc)

- Functional Safety Overview

- Brief discussion about different machineries used in manufacturing

- Flow chart of assembly process of li ion battery pack

- Technical details of manufacturing machineries

Battery Pack Assembly Line Development

- Li-ion Battery Assembly Line

- Assembly Machinery and Functional Specifications

- Different size of Module and Pack

- List of Vendors of Raw materials and Machinery supplier

Financial Projection of Li-ion battery pack Manufacturing

- Cost analysis of different machineries and manpower requirements

- Return of Investment (ROI) of li ion battery pack business

- Business projection to start a li ion battery pack business

LBO

A business guide and motivation session for startups, entrepreneurs on Lithium-ion Battery Pack Assembly business and Battery Swaping business.

Future trends in Energy Storage Battery and Customized Battery

- Energy Storage Battery Solar Street Light Battery, Outdoor Battery

- Industrial Energy Storage Battery

- Customized Battery -

Customized solution on demand for Consumer electronics, Smart Home Appliance - Floor Cleaner, Vacuum Cleaner, Smart Door Lock, Smart Camera, Home Light, Smart Lamp, drown battery etc

Trends in Indian electric vehicle domain

- 2 wheeler and 3 wheeler battery market

- Wireless charging of EV

- Battery swap technology

Business Model/Case Study

- What is the size of the EV market in India?

- Govt. Policies and Regulations

- Business models,

- Choose best product/item as per your planing

- Battery swapping,

Lab Practical

- Cell Selection - Ah testing, IR testing

- Charging Discharging test, cell balancing

- Battery Pack Construction

- Module/Pack Spot Welding

- BMS Selection and Connection (as per System Design)

- Pack testing

- Battery Pack Casing

- Battery Pack Leveling

- Battery Pack Boxing

Unit: CI

- Introduction to EV Charging technology

- Onboard charging and Off-board charging

- AC charging vs DC charging

- Conductive Charging - AC & DC

- Inductive Charging Static

- Inductive Charging Dynamic

- AC charging - Type 1,2,3

- DC charging - Chademo, Tesla, CCS

- Fast charging and its limitations

- Smart charging and applications

- Introduction of Vehicle to grid (V2G) technology

- Introduction of Wireless charging of EV

- On-road charging of EV

- Battery swap technology

- Solar-powered EVs

- Electric Vehicle Supply Equipment -

- Different types of EV charger connectors

- single-phase or three-phase socket

- SAE J1773

- CHAdeMO standard - DC fast charging

- SAE J1772 Combo

- Cords and Cables, Earthing, Lightning Protection of Electric Vehicle Charging, Residual current device (RCD)

- National & International EV Standard Codes - IEC applicable for EVSE

Unit: CSA

- site analysis for EV charging station

- Choosing the location - Public charging stations

- Site Selection Considerations, General Site Issues, URDPFI Guidelines, Planning Considerations

- Design Guidelines and Site Drawings, EVSE Typical Site Plans, Station Configuration

Unit: CSD-1

- Energy consumption

- Guidelines on Charging Infrastructure

- Public Charging Infrastructure (PCI) - Components of charging station

- Finincial Detail of charging station

- Proposed Tariff for EV Charging

- Electric Vehicle Charging Tariff in Different States of India

Unit: CSD-2

- PLANNING FOR YOUR STATION

- Solar powered electric vehicle charging station

- Calculation and selection - Components of charging station

- Finincial Detail of charging station

Unit: CSD-3

- Design On-Grid solar charging stations for a parking lot

- Plans for EVSE Installation

- Single line diagram of charging station

- EV Related Signage

Unit: SEV

- Electrical safety from the charging socket to the electric vehicle

- Different aspects of electric safety

- Electric Vehicle Charging Safety Guidelines

- Protection against electric shock, fault protection

- IEC IEC 60068-2 (1,2,14,30), IEC 61683, IEC 60227, IEC 60502 IEC 60947 part I,II, III ,IEC 61215 and more

Unit: ICS

- Charging Station Permitting

- Execution of work

- Installation Instruction

- Installing an outdoor public station

- Pedestal Charging station

- Installation Procedure

Unit: EVB

Future trends in electric vehicle domain

- Wireless charging of EV

- On-road charging of EV

- Battery swap technology

- Solar powered EVs Charging EVs from renewables

Business Model/Case Study

- What is the size of the EV market in India?

- Govt. Policies and Regulations

- Business models, Utilities , Charging space providers, Battery swapping, Digital and information technology

- Business Model

Project based Practical

Battery Project

Battery Lab

Optional: available at Head office at any time.

- Pre production Testing

- Cell Capacity Testing

- Lithium-ion Battery layout drawing & design

- Selection of Battery Pack Construction Meterials

- Cells Spot welding

- BMS Intregation

- Install in Thermal Isolation

- Battery Pack Enclosure Installation

- Battery Pack Ageing (Charging Discharging) Test

- Battery pack Quality Testing

- Preparation of Battery pack Datasheet

- Pack specification, safety sign, Leveling

- Boxing for Transport

CS Project

- Location Selection

- Volume of Vehicle Projection

- CS Design

- BOQ

- Financial Projection

- Vendor Selection

- Work Flow Presentation

- Approval Documentation

- Income and ROI Projection

- Final Project Documentation

CS Lab

Optional: available at Head office at any time.

- Read the manufacturer’s installation instructions

- Check drawings and specifications

- Calculate the total load according to the Code and ensure there is an adequate supply voltage distribution panel nearby;

- Check required conduits and excavation

- Provide physical protection from vehicle impacts, e.g., bumper posts, safety clearance or a raised platform.

- Provide for adequate lighting of the station and the surrounding area

- Clearly identify where charging vehicles are to park, using both ground markings and signage

- Follow Installation Flowchart

- Follow Electrical Connection Flowchart

- Follow Electrical Code and EVSE Code

- A separate branch circuit is installed for each station

- Follow Electrical distribution room design

- Follow Single-phase distribution wiring

- Supply line switch on

- Charger Switch on

- Troubleshooting of Charger

- Connect Charger gun with vehicle (Prototype Model), Test charging

- Disconnect Charger form Prototype Model

- Check Charging billing system

- Safety practice for CS Satff members

- Regular and Periodic Maintaince

Indian candidates Fees

Online Live Class Fees: Rs. 24999/-

Discount on Live Class Fees= 20%

Fees after discount: Rs. 19999/-

All Fees Excluding 18% GST

Foreign Candidates Fees

Online Live Class Fees: $ 470 USD

Discount on Live Class Fees= 20%

Fees after discount: $ 376 USD

All Fees Excluding 18% GST

Submit Registration

Admission Process

- Submit Registration

- Admission cell will check form data and they will inform you to pay Course fees

- Deposit Course fees

- Admission cell will send your E-registration certificate and E-library access

- Training cell will send you class schedule

- Study options:

- 2 Month (1 month in-house Technical and commercial class and onside practical, 1 month project work)

- For working Professionals: 2 Months (1 month weekend in-house Technical and commercial class and onside practical, 1 month project work)

- Training cell inform you about practical session at the end of theory class session

- Exam cell will conduct online examination and send E-Certificate, E-marksheet

- EDP Desk will provide business guide/support for you

Become an EV Expert with Verified Skill Certification

1. An Autonomous Institute registered under NCT, Govt. of India under Indian Trust Act.

2. Registered Under NGO-DARPAN, NITI Aayog Govt. of India

3. ISO 9001:2015 registered Educational Trust

4. Registered under 80G and 12A and CSR Act, Govt. of India

5. Practical and Research Lab at GATE Trust Howrah, West Bengal

6. GATE Research - Research unit of Global Advanced Training and Educational Trust. You can Write & Publish a Review/Research paper,

Interactive Session

Practical & Doubt Session

E-Library Study Materials

Online Evaluation